By: Simon Brooke :: 15 September 2024

This post extends the ideas in my previous post Thoughts on bent cycles, which you should probably read.

Volume

Assuming the position of a pilot of a feet-first recumbent cycle, I find my body fits into a volume something like this (figures in millimetres):

| From front | Width | Height above datum | Depth below datum |

|---|---|---|---|

| 0 | 240 | 500 | 0 |

| 300 | 350 | 450 | 100 |

| 600 | 400 | 450 | 0 |

| 900 | 600 | 300 | 0 |

| 1200 | 600 | 450 | 0 |

| 1600 | 500 | 600 | 0 |

The 'datum' here is the bottom of the seat. The reason that at 300 mm from the front of the envelope, I have a 100 mm depth below datum is that if I move the bottom bracket up to a height at which the pilot's heels don't go below datum, their toes (and probably other transmission gubbins) will be right in their eye-line.

Size

However the overall point here is that a naive reading of that table suggests that the entire envelope fits within a 600 mm cylinder, which, being less than 636 mm, implies that only two metre-wide lengths of carbon cloth are needed for each laminate. Which is probably true, but not, I think, helpful; because the size and shape of the hull is not in fact the minimum envelope which will enclose the pilot, but the minimum smooth aerodynamic shape which will enclose that envelope. So probably the hull needs to be bigger at its maximum sectional circumference than two metres. However, that maximum girth almost certainly comes in line with the windscreen, so you might still get away with two runs of cloth, which would be a significant saving of material.

I think this is why each of Beano, Snoopy and Woodstock has the join between the upper and lower hull shells exactly horizontal. Of course, that could also because that's the widest point on the shell, which is convenient for moulding; but I suspect in each of these three designs the lower shell is laid up with just one run of one metre wide material in each laminate.

However...

I want strength in roll-over. Which means I want a roll-over hoop behind my head, at least, and ideally one also over my knees. And consequently I'm thinking seriously of permanently bonding at least the rear part of the upper shell, and the front part, to the lower shell, and of having entry only through the windscreen aperture.

Construction

And consequently I'm thinking of moving the waistline up to the bottom of the screen aperture; and if it's going to be there, why not have a diagonal waistline, so it's at midpoint of the hull at the front (as Woodstock's is), but at the very top of the hull at the rear.

This means that the lower moulding needs to have some tumblehome, especially at the rear; which means that the two sides cannot be joined at the rear while moulding, because the shell will need to be sprung a bit to remove it from the mould. It also means that the lower moulding will almost certainly need more than one width of carbon cloth, which sort-of implies waste.

But I think that's not as serious a problem as it sounds, because the remaining two shell mouldings — the upper front and upper rear mouldings — will both be fairly small and can be made out of left overs.

There are in any case, several other smaller mouldings. There's the support and fairing structure for the transmission. There's the seat. There's probably some degree of a bulkhead supporting the rear roll-over hoop. The struts and rear axle to complete the four bar linkage could be made of timber, which would be cheaper, but they'd be lighter in carbon. It would also be nice to have thin (one laminate, probably pre-preg) carbon fairings for the spokes of all the wheels, but this is definitely optional. It would slightly reduce drag at a small cost in weight, but it's marginal.

I am thinking of using a bonded-in birch plywood eggbox structure to support a floor under the seat and cargo bay, extending forward past the rear of the front wheel, to make the lower shell more rigid and to make it easier to get in and out; and parts of the transmission housing and the rear bulkhead could also be partly plywood.

But I think I am going to need a bit more carbon (and possibly nomex) than I initially estimated. My current thinking is, to buy material to my original estimate, make the lower hull moulding, see what I have left over and then decide whether to buy more.

With a pilot volume that's 1600 mm long I think I will need to have about 200 mm in front of this for nose fairing (Woodstock appears to have only about 150 mm); behind the pilot volume I need a cargo volume that's at least a 320 mm diameter vertical cylinder 500 mm high, and then smooth fairing to a very narrow tail. So I'm thinking I need at least 600 mm behind the pilot volume, for a total hull length of 2400 mm approximately.

Gearing

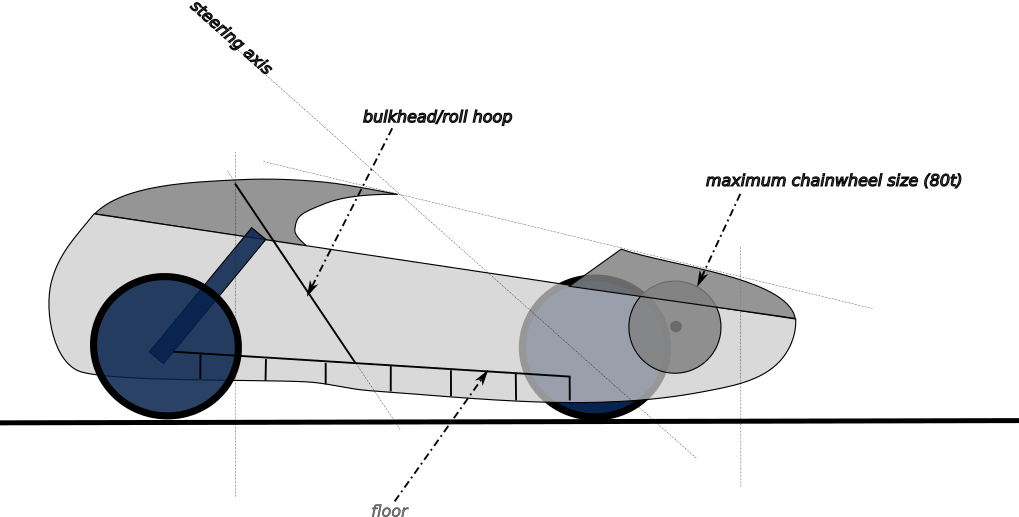

In the diagram at the top of this post, I show a chainring with 80 teeth as the maximum I'm allowing for.

Snoopy has an 85 tooth chainring driving an 11-28 10 speed cassette, and this allows the bike to be powered to 37 miles per hour on the flat, and a 35 mph average is sustainable (by a serious athlete) for 40 minutes, at a cadence of about 105. Snoopy has the same 140 mm cranks as I'm planning, but uses Shimano components; whereas I'm planning to use SRAM, so can use a 10-42 11 speed cassette. This would give me an actually higher gear than Snoopy's highest (8/1 vs 7.72/1); however, there are a number of gotchas.

First off, the chainstay distance, as I've drawn it above, is shorter than on a 700C bike by about 25%, meaning the bend on the chain when on the smallest and largest sprockets will be larger than it's designed for, meaning more rapid chain wear and possibly extra mechanical drag. It would be possible to increase the effective chain stay length by moving the wheel back towards the pilot's crotch, but not, I think, by much!

Secondly, mechanical drag increases with chain flexure, and, obviously, it flexes more to go round smaller sprockets. So there will be slightly more drag driving a ten tooth sprocket than an eleven tooth sprocket.

Thirdly, I cannot sustain cadences above 90 for any length of time using 172 mm cranks, and I've no idea yet what cadences I could sustain using 140 mm cranks.

However, I'm not a serious athlete and I'm not particularly expecting to race (certainly not competitively); I doubt I could sustain 35 mph for any length of time except perhaps downhill. So I don't need to gear for it. With 60 tooth chainring, if I can only sustain 90 cadence, I'm going to spin out at 23.6 mph (38 km/h) which feels a bit slow; I'm sure with this degree of streamlining I would be able to manage more than that on the flat. With 80 teeth at 90 cadence, I ought to reach 31.5 miles per hour (50.6 km/h) which would be very nice if I could actually sustain that on the flat, but which would certainly be useful on downhills.

Of course, it's possible that with shorter cranks I can sustain higher cadence under load; but until I have shorter cranks, I won't know this. That means that getting short cranks onto one of my bikes is an early priority.

But in summary, it seems that an 80 tooth chainring is probably needed to give me the top end speeds I'm looking for.

Steering

Think, for a moment, of the body of the tricycle not a a hull, but as a gondola in the sense of a balloon or airship gondola. It hangs from something; and what it hangs from is the virtual steering axis. Thus it's not only the caster effect which will give this vehicle dynamic directional stability; it's also gravity. The weight of the pilot will tend to bring the steering back to the straight-ahead position. That does imply that there may be some steering effects from camber, but it seems to me that it means I can be less nervous about the caster angle, provided the virtual steering axis intersects the road in front of the contact patch of the front wheel. Obviously, this intuition needs to be verified by prototyping, but the Lego is now ordered and I hope to have some prototype data by next Tuesday. A more serious problem may be that steering becomes unduly heavy, but I don't think this is likely, provided that I get the steering geometry right. Mosquito's steering is evidently reasonably light.