By: Simon Brooke :: 26 September 2024

Three updates on the tricycle project, in this third essay on it.

The state of the Mosquito velomobile project

In previous posts I have concentrated on a design based on the steering geometry of the Mosquito velomobile.

The Mosquito velomobile project, having produced a prototype which seems to work fine, has produced and sold at least a couple of production versions to customers in France which seem to have failed. The discussion of this is mostly on the velorizontal web forum, and is in French. Some messages appear to have been deleted. Here's a translation of a thread by one very unhappy customer. It's clear that there is also at least one fairly satisfied customer; but also that the project is in considerable disarray, which doesn't hugely surprise me. My impression from an interview with the main constructor of the Mosquito is that he is a fairly vulnerable person.

The full technical design of the Mosquito velomobile is online here; I've made a local copy of this, because other information related to the project seems to be disappearing from the web.

I haven't got a clear impression yet of what the supposedly fatal flaws in the design are, but my hypotheses are:

Lack of bracing for the four-bar linkage legs

On the Mosquito, the 'legs' of the four bar linkage are wooden struts which go from a quite small hinge on the (wooden) chassis to another small hinge on the axle. The axles of these hinges appear to be not more than 150mm long (I do have the drawing files, but I'm not yet sufficiently familiar with FreeCAD to completely confidently state the measurement), and they do not appear to have bearings or bushings.

The legs are inclined about 45° backwards as projected in the fore-and-aft plane, to which the pin is parallel. This means that there's a hugely unfair torsional load on the pin, and there's no bracing to resist this torsion. Triangulating the leg strut with an additional strut angled either forward or back to another hinge on the main structure of the whose axis was common with the axis of the current hinge would greatly reduce this torsion; providing either PTFE bushings or actual bearings on the hinges would improve things still further. The problem for the Mosquito, however, is that because of the chassis design there actually is no structure in a relevant position to attach such a hinge to. Indeed, there cannot be, unless either the seat was made an integral to the chassis (in which case it cannot be adjustable) or else the entire steering assembly and four bar linkage become part of the seat assembly, in which case the steering geometry (which I suspect is pretty delicate) would alter when the seat was moved.

This problem can be designed around with a monocoque hull, which I'm planning to use anyway. All I need is two points on the hull through which a common line, parallel to the centre plane and to the resting steering axis, can be projected. Furthermore, if the additional point is forward of the 'existing' point, a very small diameter stainless wire can be used in place of an additional strut, since it will be under pure tension; this would cause less aerodynamic drag.

Stiffness in the steering linkage

Several comments in the velorizontal discussions suggest that the steering on at least some Mosquito velomobile instances is unduly stiff. I read this suggestion in comments that the 'panzer style' steering controls need large amplitude movements, and that with hands off, the vehicle would maintain its current steering, which I take as implying that if turning it would continue to turn, rather than self-centring as it would if castoring was working correctly. This implies that either in (at least some) Mosquito velomobiles there isn't enough castor, or else that's there's too much stiction in the (complex!) steering mechanism.

What's needed, to achieve steering on a vehicle of this general design, is to push the hull, which forms the top 'bar' of the four bar linkage, laterally by a controlled amount relative to the rear axle, which forms the lower bar. It seems to me that a double acting hydraulic ram, with one end connected to the hull and the other to either the axle or one of the legs, would do this with minimal stiction. The problem might be that the stroke required if the pushed end were connected to the axle would be quite long — of the order of 500mm, perhaps more; and that if the pushed end were connected to a leg, the steering response might not be linear. But this is something which can be assessed in prototype, perhaps even in the Lego prototype. For a hydraulic system, the forces involved will be relatively low — something with a safe working load of 50Kg would probably be adequate. The trouble is that hydraulic cylinders as low power as this are not widely available and would probably have to be custom made. I have not yet come up with the design of a low-stiction

Poor construction/misuse

The final possibility which must be taken into account is poor construction. Several of the Mosquito-style tricycles in existence are amateur built; and while Nicholas, the main constructor of 'official' Mosquitoes is undoubtedly a fine engineer, the photographs I've seen of the machine with which the customer is so dissatisfied show so many divergences from the standard design and so many to me odd-seeming divergences that I suspect his mental health was in poor state and that this contributed to the deficiencies.

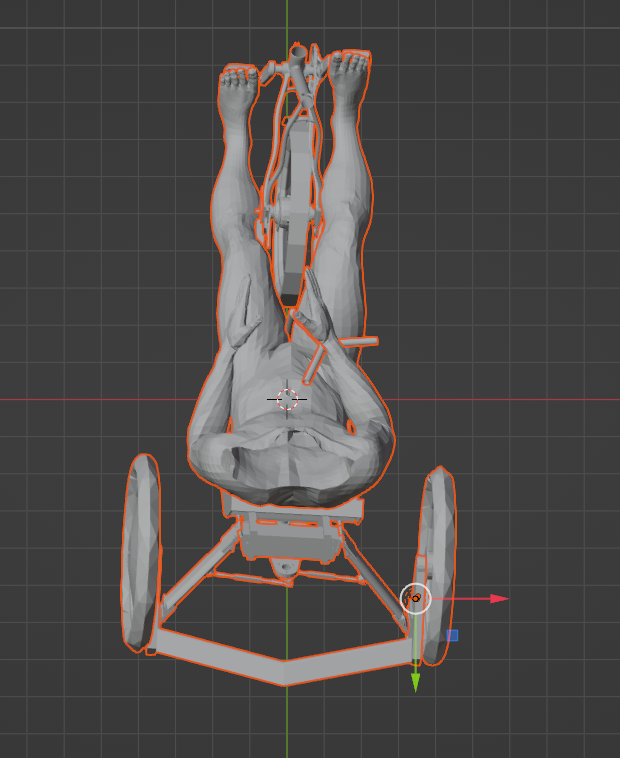

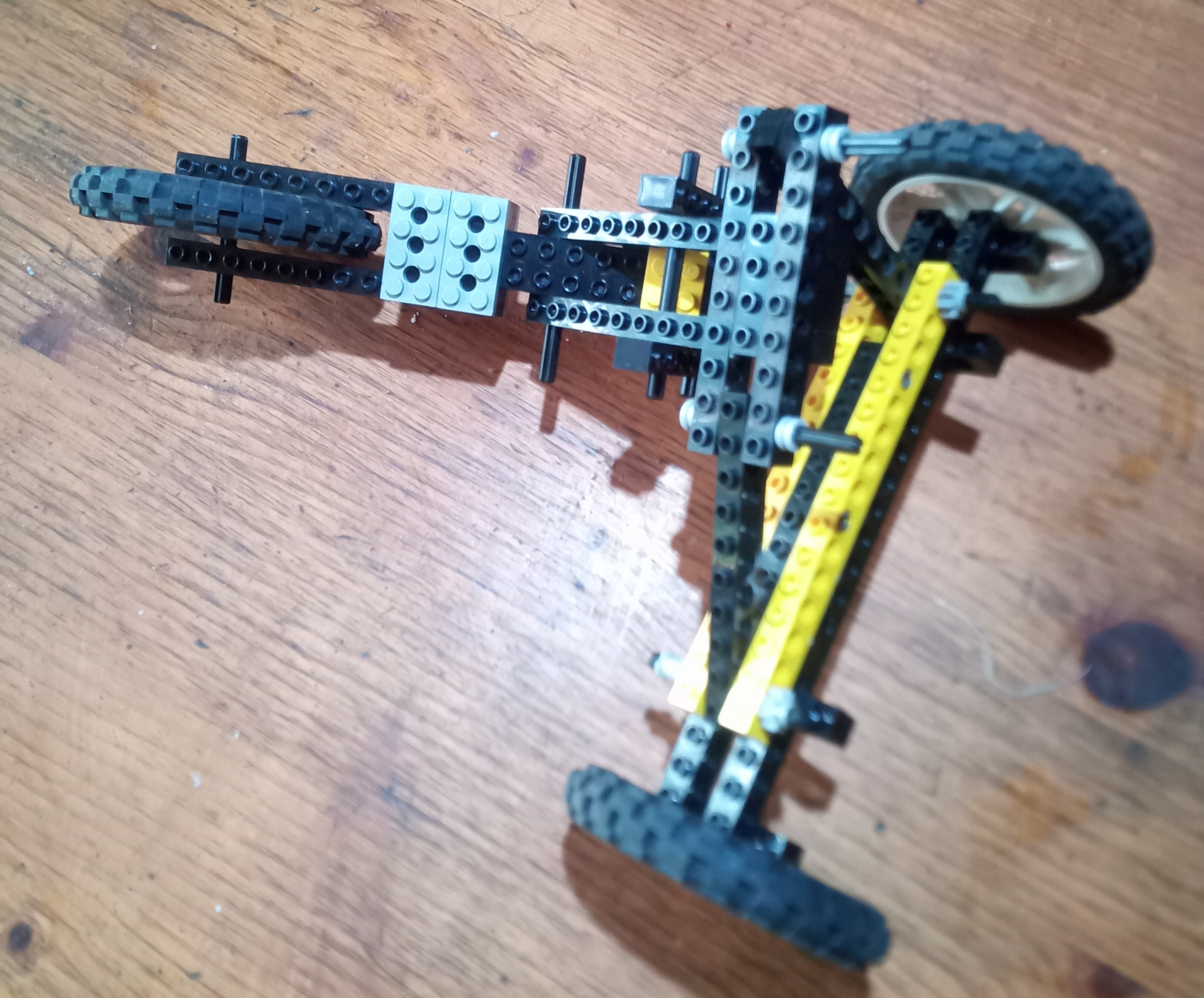

The Lego prototype

Earlier, I discussed the possibility of building a concept prototype in Lego. I did so. It — to some extent — worked. With Lego (at least, with the selection of Lego pieces I have available) it isn't possible to fine tune angles: you have, essentially, integer lengths of beams. It's clear that

- with a canted four bar linkage, there is a virtual pivot point, and it is reasonably easy to adjust the degree of cant so that the axis of the virtual pivot point intersects the ground plane ahead of the centre of pressure of the front wheel;

- with the steering at dead centre, the point at which the virtual pivot point intersects the ground plane will be straight in front of the front wheel — that is, the front wheel rolls directly towards it; but

- the virtual pivot point moves laterally as the vehicle steers, away from the side the vehicle is steering to. This may adversely affect castoring, and therefore dynamic directional stability, but the Lego prototype is not so free moving as to make it possible to really establish this.

However, the Lego model does clearly demonstrate that the central idea works, and that's a start. The turning radius that can be achieved is not tight, but it may be as tight as a conventional upright bicycle can achieve when travelling at normal speed.

It's also clear that the shorter the wheelbase in proportion to the track, the tighter it can steer — but there are some fairly obvious limitations on how short the wheelbase can go.

Adaptive cycles

Yesterday, I and two other cycling activists from Auchencairn Climate Transition, one of us herself disabled, went up to visit the Adaptive Riders' Collective in Callander, to look at and try their handcycles, and to discuss whether and how we should acquire a handcycle for people in need of one in Galloway to try. It was an extremely enjoyable, uplifting, and inspiring visit, but its relevance to this project is that the most common steering geometry for handcycles is almost identical to that I'm planning. The pivot is real — a metal head tube, just like on any conventional bicycle, rather than being virtual — but it is inclined at a very shallow angle to the ground, less than 30°, as Mosquito's is. This means, of course, that the pivot axis passes significantly below the hub of the front wheel, and I wondered whether this would cause the steering to tend to 'fall over' to each extreme of lock, rather than self centring as a normal bicycle would, but it proved that even at very modest speeds this was not a problem.

What was clear was that, as with the Lego model, with this very shallow steering pivot angle the machines could not turn tightly, and this was a problem particularly for inexperienced users (us). More experienced riders anticipated tight turns and entered them wide, and I did not see an experienced user fail to make a turn.

« Resignation of Rosie Duffield MP | | More thoughts on tricycles »